1/12

@RemiCadene

Meet the game-changer: SO-100

Crafted by @therobotstudio and @huggingface

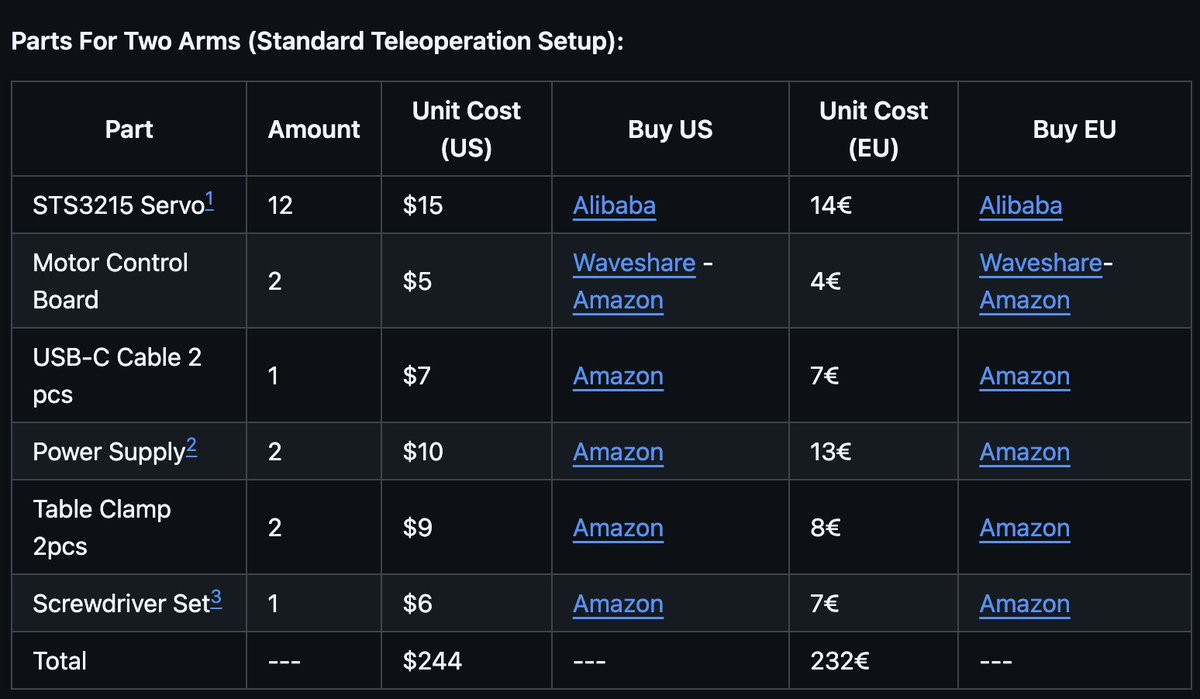

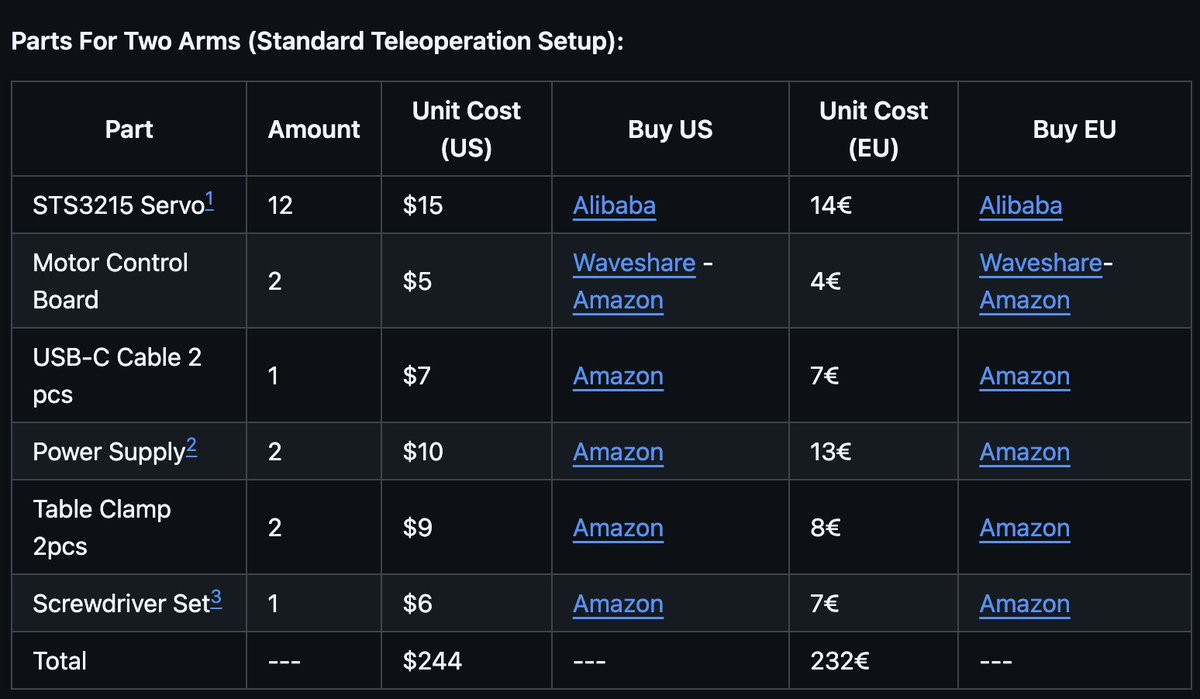

At 1/3 the cost and 2x the capabilities of our previous arms, it's the most accessible, high-performance robotic arm for $115. Easiest DIY at home!

1/ Link and details in thread

Link and details in thread

2/12

@RemiCadene

2/ Fully integrated with @LeRobotHF, the go-to for tutorials, datasets, and pretrained models — all in python

Now is the best time to get into AI for robotics!

Github: GitHub - huggingface/lerobot: LeRobot: Making AI for Robotics more accessible with end-to-end learning

LeRobot: Making AI for Robotics more accessible with end-to-end learning

Discord: Join the LeRobot Discord Server!

3/12

@RemiCadene

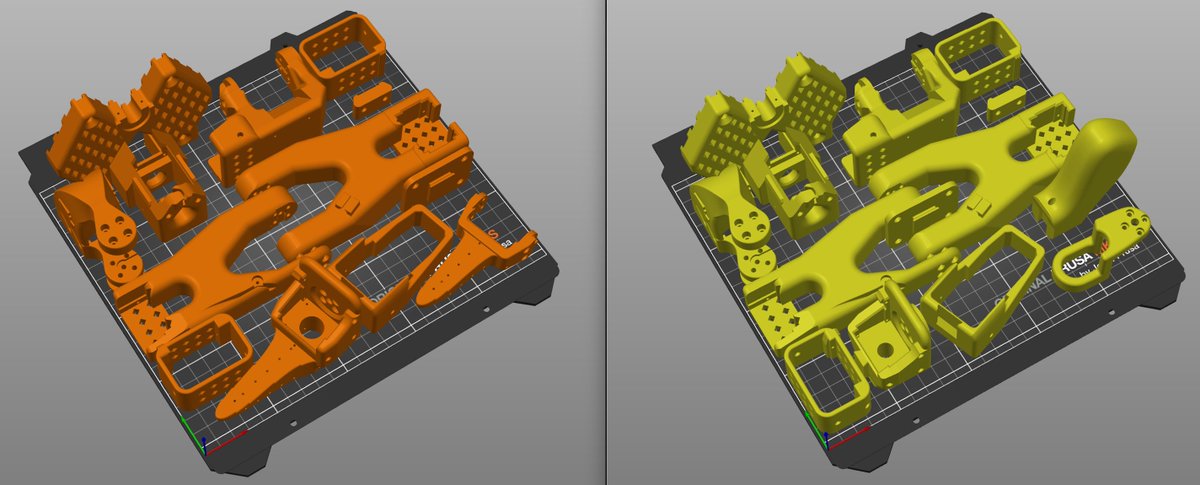

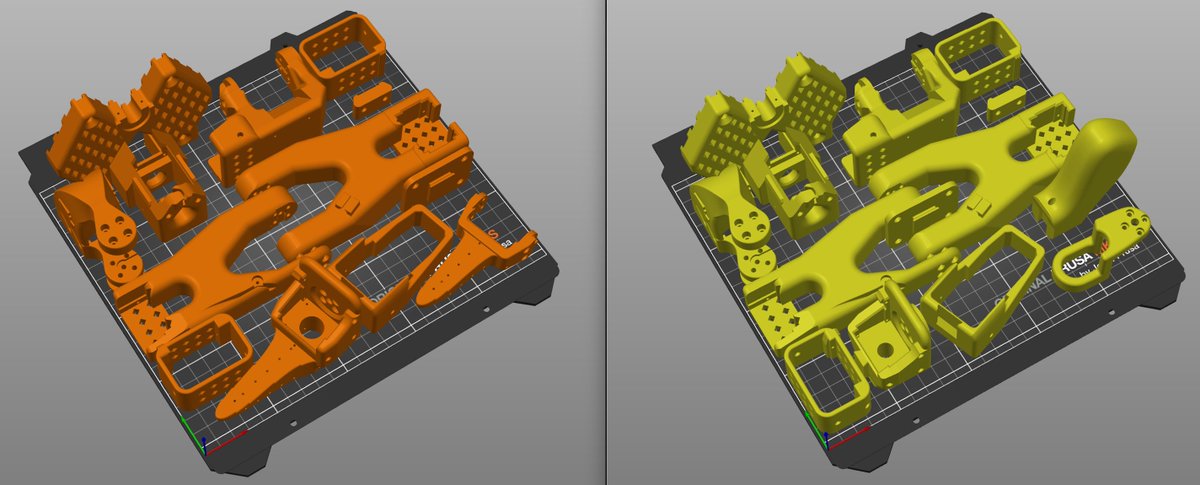

3/ Both arms are designed to fit perfectly on a standard 3D printer bed.

To ease assembling, we use the same motors

4/12

@RemiCadene

4/ Mark your calendars for October 26th-27th and join us online to build them together! (Details coming soon)

Order your parts now! GitHub - TheRobotStudio/SO-ARM100: Standard Open Arm 100

5/12

@ramkumarkoppu

any plans to sell assembled arms to use out of the box?

6/12

@RemiCadene

Possibly the off the shelf version. We are still working on it.

7/12

@thejamesvance

Looks awesome. When will capability specs be shared?

8/12

@RemiCadene

what specs do you want to know?

9/12

@marten_wikman

Is it possible to use the waveshare ST3215 servos to build this?

10/12

@RemiCadene

I dont know, but it looks like repackaged feetech motors :O

11/12

@sog_on_bird_app

I just printed the Koch arm aaaaaa

12/12

@RemiCadene

haha don't worry the koch arm is really good as well ! but we felt a more affordable arm was possible

To post tweets in this format, more info here: https://www.thecoli.com/threads/tips-and-tricks-for-posting-the-coli-megathread.984734/post-52211196

@RemiCadene

Meet the game-changer: SO-100

Crafted by @therobotstudio and @huggingface

At 1/3 the cost and 2x the capabilities of our previous arms, it's the most accessible, high-performance robotic arm for $115. Easiest DIY at home!

1/

2/12

@RemiCadene

2/ Fully integrated with @LeRobotHF, the go-to for tutorials, datasets, and pretrained models — all in python

Now is the best time to get into AI for robotics!

Github: GitHub - huggingface/lerobot:

Discord: Join the LeRobot Discord Server!

3/12

@RemiCadene

3/ Both arms are designed to fit perfectly on a standard 3D printer bed.

To ease assembling, we use the same motors

4/12

@RemiCadene

4/ Mark your calendars for October 26th-27th and join us online to build them together! (Details coming soon)

Order your parts now! GitHub - TheRobotStudio/SO-ARM100: Standard Open Arm 100

5/12

@ramkumarkoppu

any plans to sell assembled arms to use out of the box?

6/12

@RemiCadene

Possibly the off the shelf version. We are still working on it.

7/12

@thejamesvance

Looks awesome. When will capability specs be shared?

8/12

@RemiCadene

what specs do you want to know?

9/12

@marten_wikman

Is it possible to use the waveshare ST3215 servos to build this?

10/12

@RemiCadene

I dont know, but it looks like repackaged feetech motors :O

11/12

@sog_on_bird_app

I just printed the Koch arm aaaaaa

12/12

@RemiCadene

haha don't worry the koch arm is really good as well ! but we felt a more affordable arm was possible

To post tweets in this format, more info here: https://www.thecoli.com/threads/tips-and-tricks-for-posting-the-coli-megathread.984734/post-52211196